The Secret Behind Stronger Structures: Unlocking the Power of Prestressed Concrete

- Oct 27

- 4 min read

Modern construction is full of design feats that seem to defy gravity—long bridges that leap across rivers, impossibly thin stadium roofs, and wide-open industrial floors. Much of this is possible thanks to a clever engineering technique known as prestressed concrete

Understanding what is prestressed concrete is to understand how engineers solved one of the oldest challenges in building, opening the door for breathtaking new architectural possibilities.

The Challenge with Ordinary Concrete

To grasp why prestressing is so important, you first have to know concrete’s one big secret: for all its strength, it is terrible at being stretched. It has incredible compressive strength, meaning it can handle almost any amount of squeezing force. Its weakness lies in tensile strength. The moment you pull it apart, it cracks and fails.

This becomes a problem in any element that has to span a distance, like a beam. When a load presses down on the beam, it bends. While the top surface gets compressed, the bottom surface is forced to stretch. It’s this stretching that causes the cracks that ultimately lead to failure.

The Prestressed Solution

The idea behind prestressed concrete is brilliantly simple. What if you could permanently squeeze the concrete before it ever has to carry a load? That’s exactly what engineers do. They use high-strength steel tendons, stretched like massive rubber bands, to put the entire concrete element into a state of high compression.

This constant, built-in squeeze acts as a protective shield. When a load eventually tries to stretch the bottom of the beam, it first has to overcome that powerful, pre-existing compression. The result is a structure that can handle its job without ever cracking.

How Is Prestressed Concrete Made?

This internal compression is achieved through two primary methods:

Pre-tensioning: This approach is typically used in a factory setting. Steel tendons are stretched to a specific tension between two heavy anchor points. The concrete is then poured into a mould built around the taut tendons. After the concrete hardens and bonds to the steel, the ends of the tendons are cut. As the steel tries to shrink back to its original length, it transfers its massive tension force into the concrete as compression.

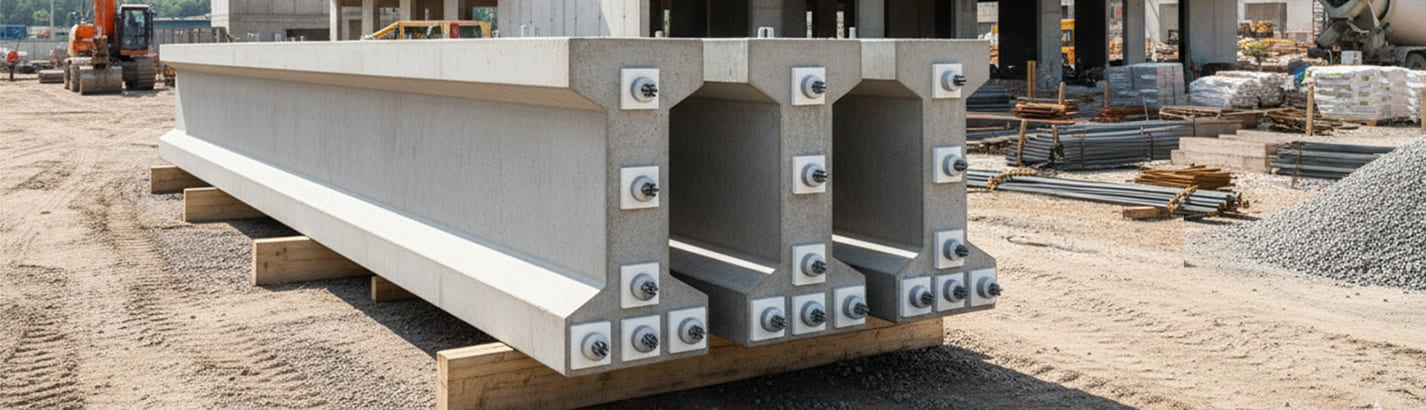

Post-tensioning: This technique brings the process to the construction site. Hollow tubes, or ducts, are placed inside the formwork where the steel will eventually go. The concrete is poured and allowed to cure. Once it's strong enough, steel tendons are threaded through the ducts, stretched with hydraulic jacks, and then locked into place with special anchors.

What is end block in prestressed concrete? |

|---|

What is the difference between prestressed and post-tensioned concrete? |

|---|

The Advantages of Prestressed Concrete

Longer Spans: Beams and slabs can stretch across much greater distances without needing columns for support.

Thinner and Lighter Sections: Because the material works more efficiently, structural elements can be designed to be much more slender and graceful, reducing material costs and the building's total weight.

Superior Durability: Keeping the concrete compressed prevents cracks from forming. This is a huge advantage, as it shields the internal steel from moisture and corrosion, vastly extending the structure's lifespan.

The Critical Role of High-Grade Cement

That internal squeeze from the steel is immense, and the concrete itself has to be exceptionally strong to handle it without being crushed. This is why producing prestressed concrete demands the use of high-performance cement, such as a 53 grade cement or another high-quality OPC cement. These provide the high early strength needed for the stressing operations and the ultimate compressive strength required for a safe and durable structure.