The Core Features of Mivan Construction (Aluminium Scaffolding) and the Impact on Construction Time

- Jul 16

- 5 min read

Modern construction demands a balance of speed, quality, and cost efficiency. Traditional construction methods often struggle to meet these demands, particularly in large-scale housing and high-rise projects. This is where Mivan Construction (Aluminium Scaffolding) offers a major advantage.

What is Mivan Construction (Aluminium Formwork System)?

Mivan Construction (Aluminium Formwork System) is a fast and structured building scaffolding method (Remove Method word) that utilizes a pre-engineered aluminium formwork developed by various companies like –Kumkang (Korea), Peri (Germany) , Doka (Austria) etc, whereas Mivan is the most popular brand name in India. known as Mivan shuttering. This system allows walls and slabs to be cast in a single pour, ensuring structural continuity and reducing construction cycles. which helps in rapid, high quality concrete construction. The technique was introduced in India in the late 1990s and was originally developed by a European company for mass housing needs.

The system is ideal for projects with repetitive layouts, such as apartment buildings or public housing. It uses Reinforced Concrete and precision-fit panels to speed up every stage of construction.

Core Features of Mivan Construction (Aluminium Formwork System)

It offers monolithic construction, meaning both walls and slabs are poured together.

The use of wall panels and slab panels ensures high dimensional accuracy.

The method relies on timely concrete pouring and early formwork removal, typically within 12–15 hours, depending on concrete strength gain.

The smooth surface finish reduces the need for extra plastering.

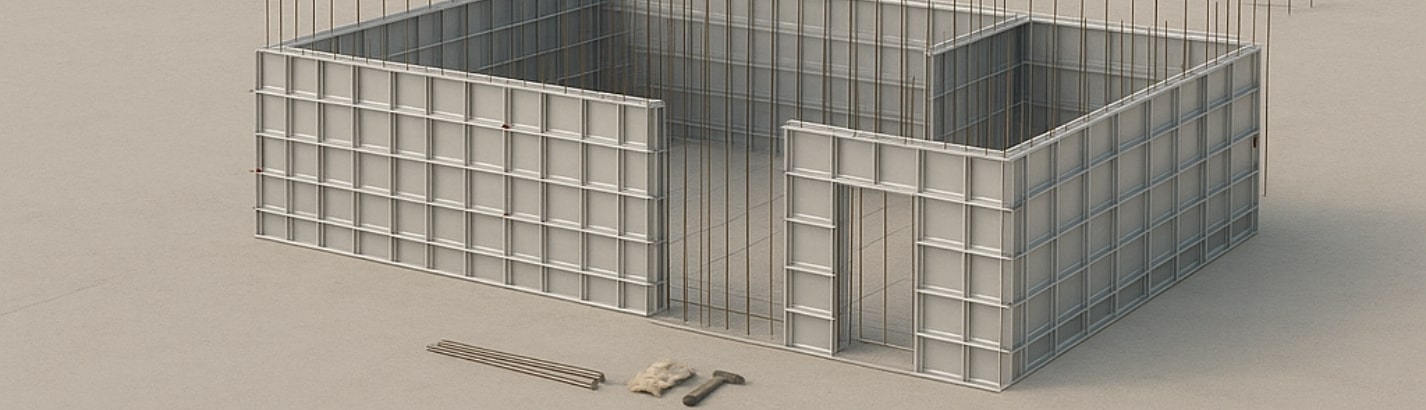

Key Components

Each structure is built using pre-designed modules, including:

Wall panels for vertical sections

Slab panels (also known as deck panels)

Soffit and beam panels

Props and alignment accessories

Special panels for windows, doors, and stairs

These pre-engineered components are assembled on-site and filled with Reinforced Concrete through controlled concrete casting procedures.

How It’s Done

The process begins with placing the panels in position. Steel reinforcement bars are fixed, and then concrete casting is done across the structure. This unified pour strengthens the building and reduces cracks.

After curing, panels are removed and reused for the next floor. Most systems allow reuse up to about 250 times, making them ideal for large-scale projects.

Why It’s Chosen

Cuts down construction time.

Maintains uniformity across floors and flats.

Offers cleaner work sites with less waste.

Requires less labour once the system is in place.

Reduces human error and improves safety on site.

Where It’s Used

You’ll often see Mivan Construction (Aluminium Formwork System) in:

Urban housing projects

Government housing schemes

Budget apartments

Smart city developments

Infrastructure with strict timelines

Mivan (Aluminium Formwork System) vs Conventional Formwork – What’s the Real Difference?

Feature | Mivan Construction(Aluminium Formwork System) | Conventional Formwork |

|---|---|---|

Speed | Much faster due to system-based formwork and quick concrete pouring | Slower because each wall and slab is built separately |

Finish | Smooth finish, needs no plaster. Saves time and material. | Uneven finish, needs extra plastering. |

Labour | Less labour is required once the system is set up. Easier to train teams | Labour-intensive, relies on skilled masons |

Material | Uses reusable aluminium formwork. Long-term cost saving | Uses wood or plywood. Limited reuse, more waste |

Accuracy | High accuracy and consistent alignment | More room for human error |

Use Cases | Ideal for high-rise and mass housing | More suited for custom or small-scale projects |

Limitations to Consider

While Mivan Construction (Aluminium Formwork System) offers several benefits, it does have some downsides:

The high initial investment in aluminium formwork may not be economically viable for small-scale or one-off projects.

Once built, the monolithic structure allows little room for future changes or custom modifications.

It requires trained workers to set up and dismantle the system, which can raise labour costs.

It works best in large, repetitive designs. It’s not ideal for custom-built or flexible layouts.

The Role of Concrete in Mivan(Aluminium Formwork System)

Reinforced Concrete is at the heart of the system. It forms the building’s entire structure. The method uses continuous concrete casting, which binds the entire frame together. Each pour is carefully timed and monitored to maintain strength and shape.

Timely concrete pouring and early formwork removal using standard-grade concrete help reduce total construction time. This makes the system not just faster but also more durable.

Final Thoughts

Mivan Construction (Aluminium Formwork System) is a proven method that meets the requirements of modern, large-scale construction projects. Its use of wall panels, Reinforced Concrete, and concrete casting helps save time, reduce costs, and improve quality. When projects need speed without cutting corners, this is a method worth choosing.

FAQs (Frequently Asked Questions)

What is Mivan construction (Aluminium Formwork System)?

Mivan construction (Aluminium Formwork System) is a method where walls and slabs are cast together using aluminium formwork. It uses Reinforced Concrete and pre-designed wall panels to build strong, uniform structures in less time. It’s mainly used in high-rise and mass housing projects.

Is Mivan(Aluminium Formwork System) better than RCC?

Mivan(Aluminium Formwork System) is not a replacement for RCC; it uses RCC in a different way. Traditional RCC is poured into wooden or plywood molds. Mivan (Aluminium Formwork System) uses aluminium formwork to pour RCC in one go. This makes it faster, cleaner, and more accurate than the usual method.

Which is better, brick or mivan(Aluminium Formwork System)?

Brickwork is slower and needs more labour. Mivan (Aluminium Formwork System) is quicker and gives a better finish. For large projects with repeat layouts, Mivan works better. Brick is still a common choice for small or custom homes that require changes during or after construction.

What is reinforcing in concrete?

Reinforcing means adding steel bars (rebars) inside concrete to make it stronger. Concrete alone can crack under tension. Reinforced Concrete handles both pressure and pulling forces, making buildings safer and more durable.

Which type of wall panel is best?

For speed and strength, aluminium wall panels used in Mivan Construction(Aluminium Formwork System) are among the best. They give a smooth finish, can be reused many times, and help reduce construction time.